In the future, these six types of textile machinery will face what kind of situation?

Publish:2023-08-18 View:388

Spinning machinery: large space for upgrading

In recent years, the cluster spinning device sales continued to increase sharply as well as combing machine sales of stable growth shows that the end-customer requirements for spinning quality is getting higher and higher.

Future growth in scale to achieve incremental spinning machine, has been unlikely. At present, cotton spinning machinery sales mainly rely on several large projects in Xinjiang, it is expected that by the second half of 2017 after the completion of these projects, this situation will change, after which the demand of enterprises will probably consider how to update their equipment and carry out upgrading.

It is expected that in the next few years, the field of spinning machinery will further increase R & D efforts to develop a new generation of high-end cotton spinning equipment, in terms of refinement, reliability, spinning suitability and other aspects to meet the users individual needs. Modern information networks and digital technology, the application of expert systems will continue to promote the gradual realization of the textile production process parameters of the online detection, display, automatic control, automatic adjustment and network monitoring development.

On the other hand, continuous spinning production process will have more room for development, with a tube, roving and combed cotton rolls of automatic transport, automatic joints and other functional equipment, as well as the ability to realize the automatic winder multi-centralized control, automatic winding process and automatic packaging equipment will be more welcome by spinning enterprises.

In addition, the traditional cotton spinning equipment market stock is very large, with the rise in labor costs and the lack of skilled workers, technological transformation space is huge.

Weaving machinery: low-consumption advantage of attention

In the textile industry as a whole, the downturn in external demand, domestic demand slowed down the market environment, by the raw materials market, the capital market uncertainty, the domestic shuttleless loom in the overall sales, imports, exports, except for water-jet looms with the same period last year compared to show a certain decline.

With the development of high-tech and new raw materials, new textile processing technologies emerge in an endless stream, enhancing the quality of textiles, broadening the application of textiles. Textile processing industry is still facing a lot of difficulties, the shortage of raw materials, energy saving and emission reduction requirements, rising labor costs, the accelerated pace of development of strategic emerging industries, etc., which all put forward a higher demand for textile equipment and processing technology.

New weaving and weaving technology and products, the main trend of development and innovation will be energy saving, equipment technology, improve quality and differentiation of innovation. Weaving enterprises will further focus on weaving equipment that can improve the labor intensity and working environment of workers. In addition, to meet new fields, new needs and promote the optimization of the industrial structure of the equipment, with energy saving, emissions reduction, low consumption, low-carbon advantages of the weaving equipment, as well as with continuous, automated, efficient, modular function of the weaving equipment will be more popular. At the same time, can be matched with the high-end parts and components will also have a lot of market space.

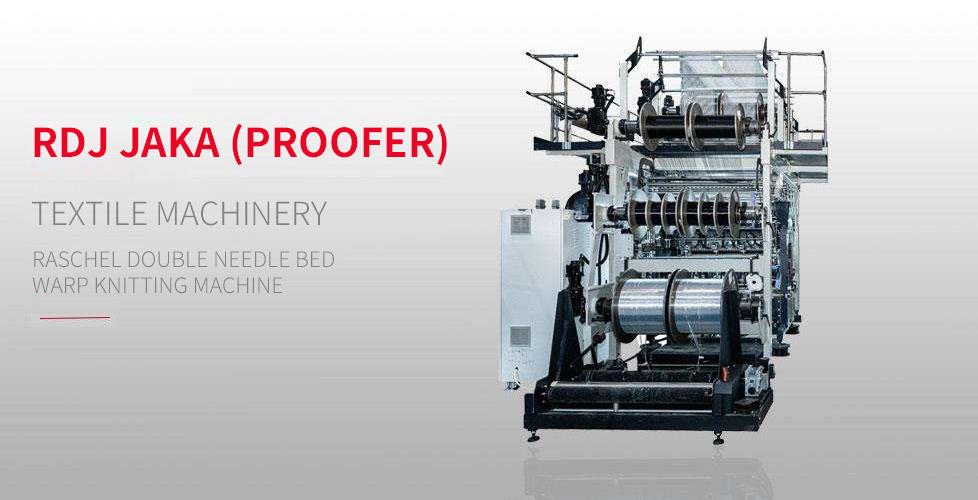

Knitting machinery: closer integration with fashion

In recent years, the knitting industry and the fashion industry combined closely, such as the widespread use of lace, driven by the multi-comb pecten warp knitting machine continued for several years of high-speed development; womens bottoms of a large area of popularity, driven by a large number of 8-inch circular weft machine equipment needs. As consumers further pursue personalization and fashion industry continues to develop, the corresponding knitting machinery also holds broad prospects for development.

Flat knitting machine market will continue the good momentum. On the one hand, the old computerized flat knitting machine knitting speed and knitting pattern ability of domestic sweater knitting enterprises can not meet the production demand, a large number of equipment needs to be eliminated and updated; on the other hand, for knitting knitted footwear production enterprises of flat knitting machine equipment to maintain a strong demand.

At present, the fully-formed upper machine is the trend of the development of knitted upper machine, and it is expected that there is still room for development in the future in terms of footwear technology and materials. It is worth noting that the domestic circular weft machine enterprises began to focus on research and development of shoe circular weft machine, part of the enterprise has a prototype; benefited from the rise of artificial fur and sports footwear and other products, double needle beds and high-speed warp knitting machine will be expanded and extended; with the industrial knitwear applications in the field of vigorous development, the user of multi-axial warp knitting machine demand will continue to grow.

Printing and dyeing machinery: green and energy-saving

Traditional printing machine is still the mainstream products in the market, large flowers back to the round screen printing machine is welcomed by the market. At present, the combination of digital + oval cutter in Guangdong market is more popular, while the combination of digital + traditional printing machine to be tested in the market.

Printing and dyeing machinery industry is still facing a lot of problems, such as the overall profit is low, many companies are difficult to invest funds in new research and development, research and development capabilities are generally insufficient; poor foresight of the market, the new product is less, and often many companies flock to a certain type of product market, the production of homogeneous products, which soon leads to the product market saturation.

Digital inkjet printing with diversification, small batch, personalized customization and other characteristics, inkjet printing speed has been improved, but still a lot of difference with the traditional printing machine; printheads and other key technologies in the hands of a small number of foreign enterprises; downstream market margins are shrinking rapidly, some inkjet printing machine manufacturers began to reduce production, these issues constrain the development of digital printing.

Attractive market prospects to attract more and more companies to invest in the development of digital inkjet printing machine and its supporting products. At present, the domestic market digital printing machine is almost occupied by foreign equipment, domestic high-speed equipment is less, high investment faces the situation of low output, the enterprise pressure is huge.

With the deep adjustment of the market, eliminating backwardness and promoting the high-end process has become the norm. Green textile is the theme of the development of Chinas textile industry, environmental protection, energy saving, short processes, digital monitoring and intelligence is still the direction of the development of printing and dyeing machinery, can improve resource efficiency, reduce costs, effectively reduce pollution of the equipment will be welcomed by the market.

Accompanied by the continuous improvement of the level of technology, high-speed printer printing speed has been close to the flat screen printing, while the production cost is gradually decreasing, is ushering in a period of rapid growth. Some experts expect that by 2019, the production of digital printed fabric will account for 7.2% of the domestic production of printed fabric.

Chemical fiber machinery: technical reform is still a positive factor

With the return of rational investment in the chemical fiber industry, the domestic chemical fiber industry new production capacity projects to reduce, chemical fiber machinery market demand declined. Chemical fiber equipment market sales continue to go down, chemical fiber equipment manufacturers in the product sales price competition is fierce, downstream users pick up the enthusiasm is not high, but the technical reform is still a positive factor in the chemical fiber market.

With the gradual recovery of the downstream chemical fiber market, polyester, nylon production start rate of up to 70% or more, the domestic chemical fiber enterprises to increase investment, is expected to improve the chemical fiber market in the future.

Nonwovens machinery: spunlace production line situation is optimistic

With the downstream industry investment slowdown corresponds to the demand for low-end equipment has decreased significantly, the mid-range and even high-end demand increased, the business situation is more and more significant differentiation, the order to the stronger technical reserves, the production of larger enterprises to focus on.

Some overseas enterprises for the Chinese market demand characteristics of the introduction of some new models, but also shorten the delivery period. It is worth mentioning that the pile needle felting machine in the past two years, the market demand is strong, this part of the unit machine sales for the relevant mechanical enterprises have brought considerable income.

At present, some of the market is worth paying attention to new trends, namely, high speed and high yield of the new equipment increment is more, the speed of equipment renewal. Some enterprises are developing such as direct spinning plus spunbond process route. In addition to the traditional major products, the domestic also appeared in PLA, PPS, PE, elastic materials and other aspects of the demand for processing equipment. Nevertheless, the domestic non-woven equipment market is still relatively serious homogenization phenomenon, more than 100 production line capacity per year, in addition to supplying the domestic market, there are many into the international market. And in the face of future market demand, nonwovens machinery will be high-speed high-yield, differentiated direction.

In recent years, the cluster spinning device sales continued to increase sharply as well as combing machine sales of stable growth shows that the end-customer requirements for spinning quality is getting higher and higher.

Future growth in scale to achieve incremental spinning machine, has been unlikely. At present, cotton spinning machinery sales mainly rely on several large projects in Xinjiang, it is expected that by the second half of 2017 after the completion of these projects, this situation will change, after which the demand of enterprises will probably consider how to update their equipment and carry out upgrading.

It is expected that in the next few years, the field of spinning machinery will further increase R & D efforts to develop a new generation of high-end cotton spinning equipment, in terms of refinement, reliability, spinning suitability and other aspects to meet the users individual needs. Modern information networks and digital technology, the application of expert systems will continue to promote the gradual realization of the textile production process parameters of the online detection, display, automatic control, automatic adjustment and network monitoring development.

On the other hand, continuous spinning production process will have more room for development, with a tube, roving and combed cotton rolls of automatic transport, automatic joints and other functional equipment, as well as the ability to realize the automatic winder multi-centralized control, automatic winding process and automatic packaging equipment will be more welcome by spinning enterprises.

In addition, the traditional cotton spinning equipment market stock is very large, with the rise in labor costs and the lack of skilled workers, technological transformation space is huge.

Weaving machinery: low-consumption advantage of attention

In the textile industry as a whole, the downturn in external demand, domestic demand slowed down the market environment, by the raw materials market, the capital market uncertainty, the domestic shuttleless loom in the overall sales, imports, exports, except for water-jet looms with the same period last year compared to show a certain decline.

With the development of high-tech and new raw materials, new textile processing technologies emerge in an endless stream, enhancing the quality of textiles, broadening the application of textiles. Textile processing industry is still facing a lot of difficulties, the shortage of raw materials, energy saving and emission reduction requirements, rising labor costs, the accelerated pace of development of strategic emerging industries, etc., which all put forward a higher demand for textile equipment and processing technology.

New weaving and weaving technology and products, the main trend of development and innovation will be energy saving, equipment technology, improve quality and differentiation of innovation. Weaving enterprises will further focus on weaving equipment that can improve the labor intensity and working environment of workers. In addition, to meet new fields, new needs and promote the optimization of the industrial structure of the equipment, with energy saving, emissions reduction, low consumption, low-carbon advantages of the weaving equipment, as well as with continuous, automated, efficient, modular function of the weaving equipment will be more popular. At the same time, can be matched with the high-end parts and components will also have a lot of market space.

Knitting machinery: closer integration with fashion

In recent years, the knitting industry and the fashion industry combined closely, such as the widespread use of lace, driven by the multi-comb pecten warp knitting machine continued for several years of high-speed development; womens bottoms of a large area of popularity, driven by a large number of 8-inch circular weft machine equipment needs. As consumers further pursue personalization and fashion industry continues to develop, the corresponding knitting machinery also holds broad prospects for development.

Flat knitting machine market will continue the good momentum. On the one hand, the old computerized flat knitting machine knitting speed and knitting pattern ability of domestic sweater knitting enterprises can not meet the production demand, a large number of equipment needs to be eliminated and updated; on the other hand, for knitting knitted footwear production enterprises of flat knitting machine equipment to maintain a strong demand.

At present, the fully-formed upper machine is the trend of the development of knitted upper machine, and it is expected that there is still room for development in the future in terms of footwear technology and materials. It is worth noting that the domestic circular weft machine enterprises began to focus on research and development of shoe circular weft machine, part of the enterprise has a prototype; benefited from the rise of artificial fur and sports footwear and other products, double needle beds and high-speed warp knitting machine will be expanded and extended; with the industrial knitwear applications in the field of vigorous development, the user of multi-axial warp knitting machine demand will continue to grow.

Printing and dyeing machinery: green and energy-saving

Traditional printing machine is still the mainstream products in the market, large flowers back to the round screen printing machine is welcomed by the market. At present, the combination of digital + oval cutter in Guangdong market is more popular, while the combination of digital + traditional printing machine to be tested in the market.

Printing and dyeing machinery industry is still facing a lot of problems, such as the overall profit is low, many companies are difficult to invest funds in new research and development, research and development capabilities are generally insufficient; poor foresight of the market, the new product is less, and often many companies flock to a certain type of product market, the production of homogeneous products, which soon leads to the product market saturation.

Digital inkjet printing with diversification, small batch, personalized customization and other characteristics, inkjet printing speed has been improved, but still a lot of difference with the traditional printing machine; printheads and other key technologies in the hands of a small number of foreign enterprises; downstream market margins are shrinking rapidly, some inkjet printing machine manufacturers began to reduce production, these issues constrain the development of digital printing.

Attractive market prospects to attract more and more companies to invest in the development of digital inkjet printing machine and its supporting products. At present, the domestic market digital printing machine is almost occupied by foreign equipment, domestic high-speed equipment is less, high investment faces the situation of low output, the enterprise pressure is huge.

With the deep adjustment of the market, eliminating backwardness and promoting the high-end process has become the norm. Green textile is the theme of the development of Chinas textile industry, environmental protection, energy saving, short processes, digital monitoring and intelligence is still the direction of the development of printing and dyeing machinery, can improve resource efficiency, reduce costs, effectively reduce pollution of the equipment will be welcomed by the market.

Accompanied by the continuous improvement of the level of technology, high-speed printer printing speed has been close to the flat screen printing, while the production cost is gradually decreasing, is ushering in a period of rapid growth. Some experts expect that by 2019, the production of digital printed fabric will account for 7.2% of the domestic production of printed fabric.

Chemical fiber machinery: technical reform is still a positive factor

With the return of rational investment in the chemical fiber industry, the domestic chemical fiber industry new production capacity projects to reduce, chemical fiber machinery market demand declined. Chemical fiber equipment market sales continue to go down, chemical fiber equipment manufacturers in the product sales price competition is fierce, downstream users pick up the enthusiasm is not high, but the technical reform is still a positive factor in the chemical fiber market.

With the gradual recovery of the downstream chemical fiber market, polyester, nylon production start rate of up to 70% or more, the domestic chemical fiber enterprises to increase investment, is expected to improve the chemical fiber market in the future.

Nonwovens machinery: spunlace production line situation is optimistic

With the downstream industry investment slowdown corresponds to the demand for low-end equipment has decreased significantly, the mid-range and even high-end demand increased, the business situation is more and more significant differentiation, the order to the stronger technical reserves, the production of larger enterprises to focus on.

Some overseas enterprises for the Chinese market demand characteristics of the introduction of some new models, but also shorten the delivery period. It is worth mentioning that the pile needle felting machine in the past two years, the market demand is strong, this part of the unit machine sales for the relevant mechanical enterprises have brought considerable income.

At present, some of the market is worth paying attention to new trends, namely, high speed and high yield of the new equipment increment is more, the speed of equipment renewal. Some enterprises are developing such as direct spinning plus spunbond process route. In addition to the traditional major products, the domestic also appeared in PLA, PPS, PE, elastic materials and other aspects of the demand for processing equipment. Nevertheless, the domestic non-woven equipment market is still relatively serious homogenization phenomenon, more than 100 production line capacity per year, in addition to supplying the domestic market, there are many into the international market. And in the face of future market demand, nonwovens machinery will be high-speed high-yield, differentiated direction.

Recommend

More+

News

More+

History of Textile Machinery

2023-08-18

18659518651

18659518651

閩公網(wǎng)安備35058202000839號

閩公網(wǎng)安備35058202000839號

18659518651

18659518651