What are the six categories of textile machinery? What is the main role

Publish:2023-08-18 View:361

Textile machinery is the natural fiber or chemical fiber processing into textiles required by a variety of mechanical equipment. Cotton, leprosy, silk, wool and other different fibers processed into textiles require different processes, some completely different, so the need for a variety of machines, a wide variety. Classification as long as there are spinning equipment, weaving equipment, printing and dyeing equipment, finishing equipment, chemical fiber pumping equipment, reeling equipment and non-woven fabric equipment. Spinning equipment is divided into processing short fibers and processing long fibers two categories. Cotton and cotton chemical fiber is a short fiber class, wool, hemp, silk and its blended chemical fiber is a long fiber class. Two types of fibers are processed differently, the equipment can not be universal, only some of the machine design principles are similar. Even if the same type of equipment, machine structure is similar, but due to the nature of the raw materials and fabric requirements are different, generally can not be common.

Spinning equipment is mainly divided into the processing of short fibers and processing of long fibers in two categories, due to the many varieties. Machine structure, use and performance are different. According to its order in the process is divided into open and clear cotton machinery, carding machine, combing machine, into the volume of the machine, winding machine, and yarn machine, and strip machine, coarse, warping process yarn machine, spinning machine, rotor spinning machine, wool and linen spinning machinery.

Weaving equipment according to its process of winding process, warping process, wearing process, weaving process, finishing process.

Printing and dyeing equipment burnishing machine (cloth surface burnishing), decooking and bleaching machine (cloth surface slurry back off), mercerizing machine (so that the fabric fibers are neatly arranged, the cloth has a glossy surface, the dye adsorption better point), uniform rolling car (fabric dyeing), shaping machine (fabric shaping), pre-shrinking machine (to control the shrinkage of the fabric).

Finishing equipment is the textile finishing equipment to be used mainly coating, calendering, printing, washing, nitrogen washing, sand washing, embossing, punching, shaping, embroidery, hot stamping and so on.

The end of the 19th century the introduction of synthetic fibers, broadening the field of textile machinery, adding a chemical fiber machinery category. Peoples need for synthetic fibers to promote the growth of synthetic fiber spinning equipment to large-scale (spinning screw diameter up to 200 mm, a single spinning machine to reach 100 tons of daily output) and high-speed (spinning speed up to 3,000 ~ 4,000 m / min) the direction of development. The worlds fast-growing synthetic fiber industry in the country, almost in 5 to 6 years equipment renewal once, the number of machines in 10 years on the double. Nearly 20 years of spinning and weaving equipment, in order to adapt to the pure spinning of chemical fibers or blended spinning with natural fibers made a number of local improvements, such as expanding the range of draft agencies suitable for spinning the length of fibers to eliminate static electricity on the fiber. In dyeing and finishing the development of high temperature and high pressure dyeing equipment, heat shaping equipment, resin finishing equipment and loose finishing equipment.

Nonwoven equipment to textile fibers as raw materials after bonding, fusion or other chemical and mechanical methods of processing textiles. This textile does not go through the traditional spinning, weaving or knitting process, also known as non-woven fabrics, non-woven fabrics.

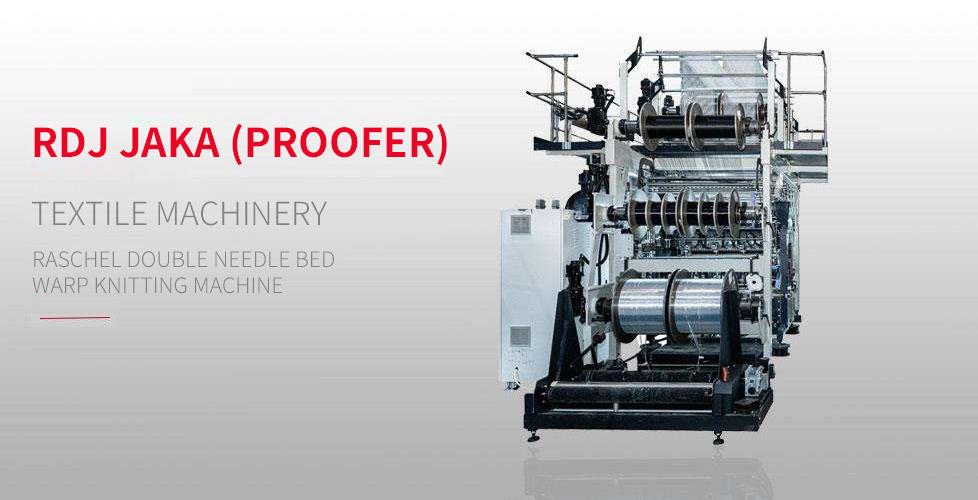

Jinjiang Pengtai Machinery Technology Co., Ltd. is a technology-based enterprise engaged in the research and development, manufacturing and sales of textile machinery and related services. Located in Jinjiang City Economic Development Zone Wuli Park, the company actively involved in the development of new products, continuous development, innovation. The leading product double needle bed warp knitting machine has won a number of national technology patents.

Spinning equipment is mainly divided into the processing of short fibers and processing of long fibers in two categories, due to the many varieties. Machine structure, use and performance are different. According to its order in the process is divided into open and clear cotton machinery, carding machine, combing machine, into the volume of the machine, winding machine, and yarn machine, and strip machine, coarse, warping process yarn machine, spinning machine, rotor spinning machine, wool and linen spinning machinery.

Weaving equipment according to its process of winding process, warping process, wearing process, weaving process, finishing process.

Printing and dyeing equipment burnishing machine (cloth surface burnishing), decooking and bleaching machine (cloth surface slurry back off), mercerizing machine (so that the fabric fibers are neatly arranged, the cloth has a glossy surface, the dye adsorption better point), uniform rolling car (fabric dyeing), shaping machine (fabric shaping), pre-shrinking machine (to control the shrinkage of the fabric).

Finishing equipment is the textile finishing equipment to be used mainly coating, calendering, printing, washing, nitrogen washing, sand washing, embossing, punching, shaping, embroidery, hot stamping and so on.

The end of the 19th century the introduction of synthetic fibers, broadening the field of textile machinery, adding a chemical fiber machinery category. Peoples need for synthetic fibers to promote the growth of synthetic fiber spinning equipment to large-scale (spinning screw diameter up to 200 mm, a single spinning machine to reach 100 tons of daily output) and high-speed (spinning speed up to 3,000 ~ 4,000 m / min) the direction of development. The worlds fast-growing synthetic fiber industry in the country, almost in 5 to 6 years equipment renewal once, the number of machines in 10 years on the double. Nearly 20 years of spinning and weaving equipment, in order to adapt to the pure spinning of chemical fibers or blended spinning with natural fibers made a number of local improvements, such as expanding the range of draft agencies suitable for spinning the length of fibers to eliminate static electricity on the fiber. In dyeing and finishing the development of high temperature and high pressure dyeing equipment, heat shaping equipment, resin finishing equipment and loose finishing equipment.

Nonwoven equipment to textile fibers as raw materials after bonding, fusion or other chemical and mechanical methods of processing textiles. This textile does not go through the traditional spinning, weaving or knitting process, also known as non-woven fabrics, non-woven fabrics.

Jinjiang Pengtai Machinery Technology Co., Ltd. is a technology-based enterprise engaged in the research and development, manufacturing and sales of textile machinery and related services. Located in Jinjiang City Economic Development Zone Wuli Park, the company actively involved in the development of new products, continuous development, innovation. The leading product double needle bed warp knitting machine has won a number of national technology patents.

Recommend

More+

News

More+

History of Textile Machinery

2023-08-18

18659518651

18659518651

閩公網(wǎng)安備35058202000839號

閩公網(wǎng)安備35058202000839號

18659518651

18659518651